Precision MANUFACTURING

Capitol Aluminum & Glass Corporation

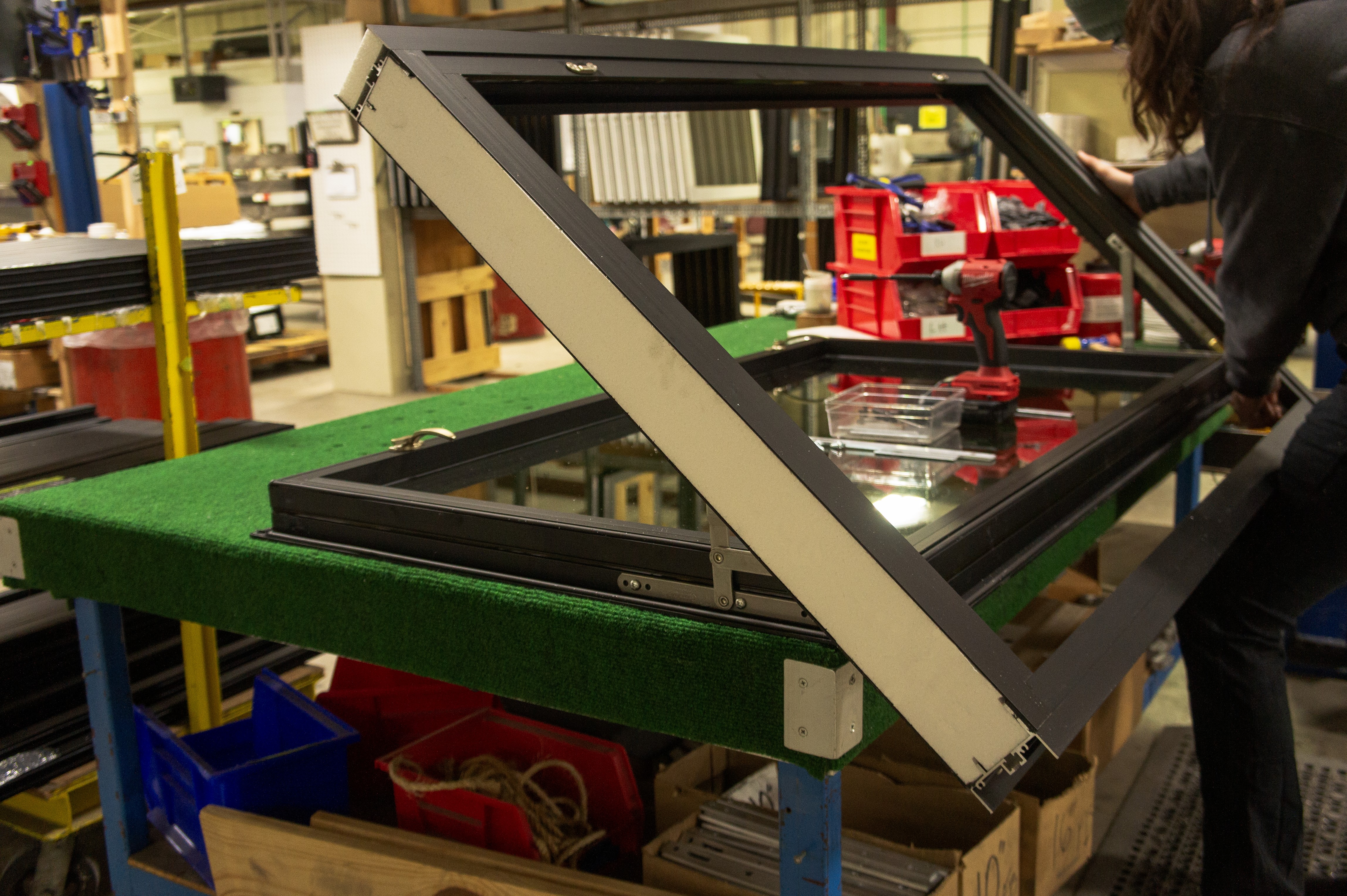

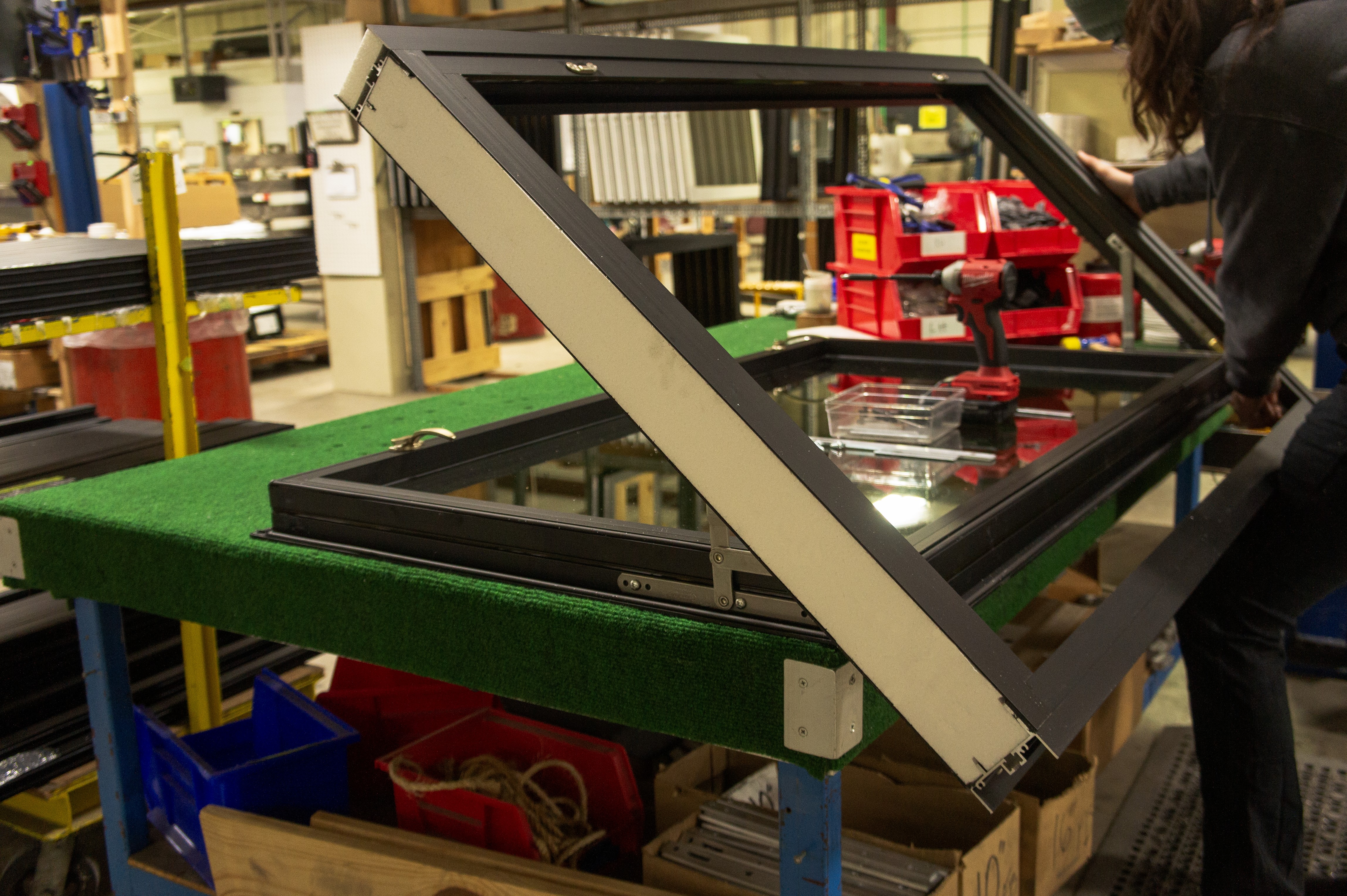

At Capitol Aluminum & Glass Corporation, our manufacturing process is the heart of our commitment to quality, innovation, and customer satisfaction. With a state-of-the-art 75,000 square foot facility in Bellevue, Ohio, we combine decades of experience with cutting-edge technology to produce superior aluminum window, entrance, storefront, and curtain wall systems.

Our Manufacturing Edge

Our Manufacturing Edge

We utilize specialized automated production equipment for precise cutting, machining, and assembly of aluminum extrusions. Our technical staff are proficient in AutoCAD, CNC Programming, and systems design, ensuring accuracy from concept to completion. We integrate lean manufacturing concepts to optimize efficiency, minimize waste, and ensure a streamlined production process. This commitment to lean practices translates into faster turnaround times and consistent quality for our clients.

Our extensive experience, dating back to 1956, means we have an unparalleled understanding of aluminum and glass fabrication. We've even developed our own specialized equipment over the years to achieve higher quality and standardized systems. Every Capitol product undergoes rigorous in-house testing before being sent to independent testing laboratories for certification. This meticulous approach guarantees that our products meet and exceed industry standards for performance, durability, and energy efficiency. Our entire order processing system is fully computerized with custom-designed software, allowing us to efficiently manage projects and respond to our customers' unique needs with precision and speed.

The Benefits of In-House Manufacturing:

Choosing Capitol Aluminum & Glass means benefiting from our integrated, in-house manufacturing capabilities:

- Uncompromised Quality: By controlling every step of the manufacturing process, from raw materials to finished product, we maintain the highest standards of quality and craftsmanship.

- Customization and Flexibility: Our in-house capabilities allow for greater flexibility in design and production, enabling us to create custom solutions tailored to the specific aesthetic and functional requirements of your project.

- Faster Project Turnaround: Because we manufacture our systems in-house, we have direct control over the production timeline. This means more efficient project completion and delivery, especially when Capitol Aluminum & Glass is also providing installation.

- Cost-Effectiveness: Our optimized manufacturing processes and direct-to-customer model help reduce overheads, providing you with high-quality products at competitive prices.

- Enhanced Problem Solving: Our experienced team can quickly address any challenges that arise during production, ensuring a smooth and successful outcome for your project.

Sustainable Practices:

Capitol Aluminum & Glass is committed to sustainable manufacturing practices. We strive to minimize our environmental footprint by:

- Optimizing Material Usage: Our precise cutting and machining processes reduce material waste.

- Recycling Aluminum: Aluminum is a highly recyclable material, and we prioritize its use and proper recycling within our operations.

- Energy-Efficient Production: We continually seek ways to improve the energy efficiency of our manufacturing processes, contributing to a greener future.

When you choose Capitol Aluminum & Glass Corporation, you're choosing a partner dedicated to delivering superior aluminum and glass solutions, manufactured with precision, expertise, and a commitment to your project's success.